Sign up for

XponentialTimes

The latest in exponential technologies, straight to your inbox

Nothing is more exponential than spam. We respect your privacy and never share your personal information.

Ultrafast polymer production 3D printer manufacturer, Nexa3D, has partnered with Royal DSM to speed up the adoption of sustainable additive manufacturing and production.

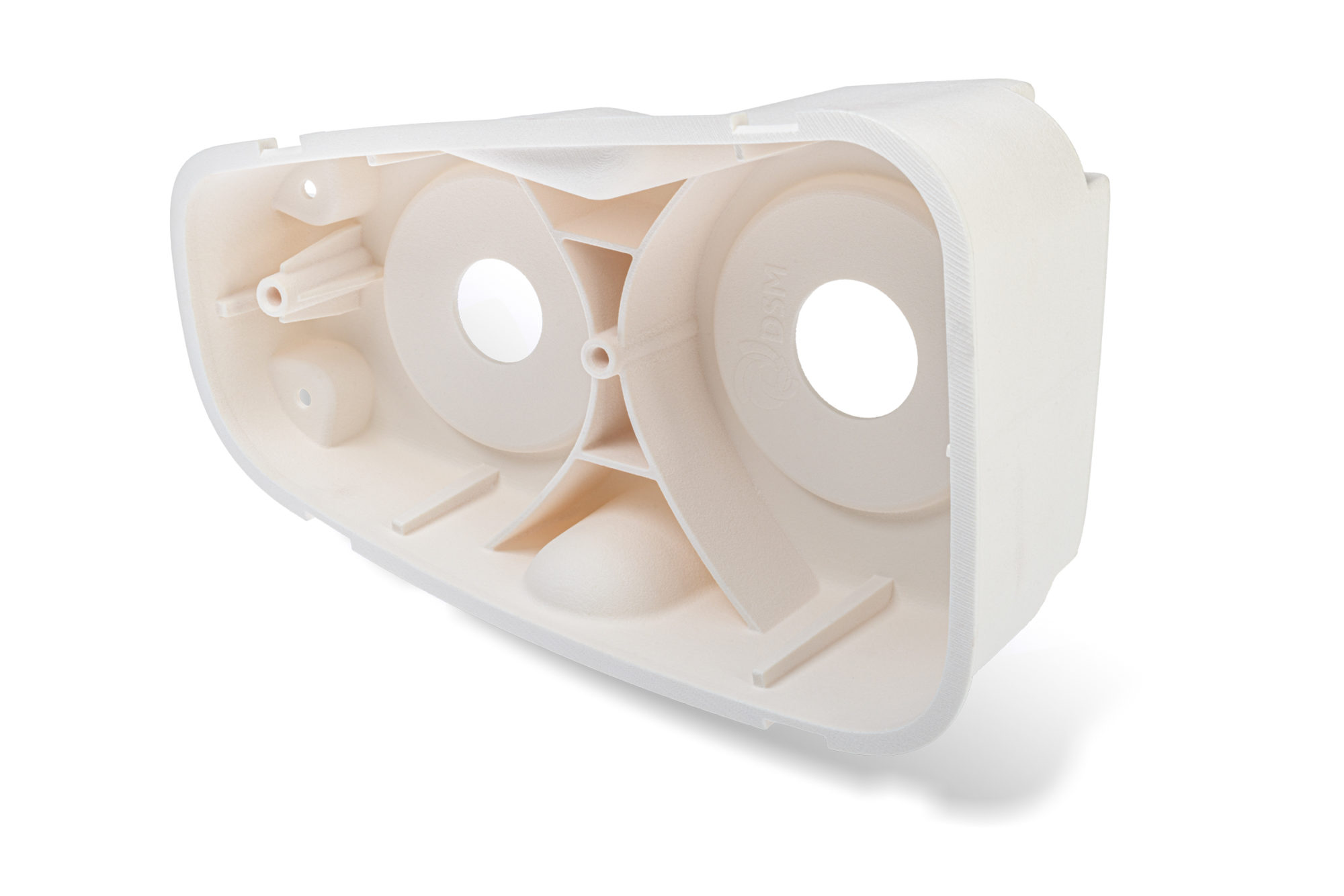

The partnership will fast track the availability of Nexa3D’s Quantum Laser Sintering (QLS) 350 systems with DSM’s sustainable laser sintering powders for series production. In addition, DSM’s first polybutylene terephthalate (PBT) laser sintering material, Arnite T AM1210, will be included with every QLS 350 system sold commercially from the first quarter of 2021.

According to DSM, Arnite T AM1210 is the first-ever PBT powder commercially available for series production of industrial and automotive electronics.

“We are very excited to partner with Nexa3D, the company that is breaking traditional additive manufacturing speed and productivity barriers, to deliver our first-ever PBT laser sintering material through their ultrafast QLS 350 system,” said Hugo da Silva, VP of Additive Manufacturing at DSM.

PBT powders in additive manufacturing

Driven by innovations in the automotive and electronics industries, the use of laser sintering PBT materials is expected to increase significantly over the next decade, in part due to the need to minimize issues surrounding the corrosion of metals and their associated high costs.

Earlier this year, the Mitsubishi Chemical Corporation (MCC) and German new materials start-up company, AM Polymers GmbH (AMP), partnered to co-develop polybutylene terephthalate (PBT) powder products for industrial 3D printing using PBT feedstock, and a beta version of AMP’s Rolaserit PBT01 powder.

In January, French 3D printer producer Prodways sold two of its ProMaker P2000 ST 3D printers to DSM, allowing the company to test its powders for high-temperature SLS 3D printing. Prio to this, DSM used Prodways’ ProMaker P4500 3D printer to print Arnite T AM1210.

Arnite T AM1210 is well-suited suited to the automotive and electronics industries thanks to its electrical, mechanical, and flame-retardant properties. Developed for a wide sinter window, the powder is very easy to print, and is environmentally friendly with a reuse rate of more than 60%. Arnite T AM1210 is also recyclable to the extent that the material can be brought reused in the powder bed process.