Sign up for

XponentialTimes

The latest in exponential technologies, straight to your inbox

Nothing is more exponential than spam. We respect your privacy and never share your personal information.

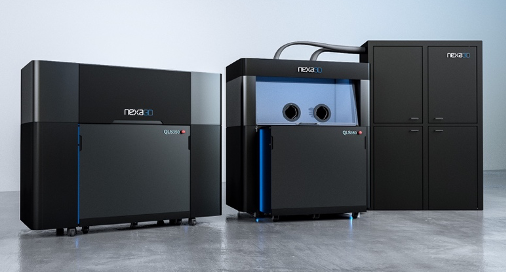

Geleen, Netherlands and Ventura, California, September 15, 2020 – Royal DSM, a global science-based company in Nutrition, Health and Sustainable Living, and Nexa3D, the maker of ultrafast polymer production 3D printers, today announced a partnership to fast track the availability of Nexa3D’s QLS-350 systems with DSM’s supply chain-approved laser sintering powders for series production. Under this collaboration, Nexa3D plans to immediately include DSM’s first-ever PBT laser sintering material, Arnite® T AM1210 (P), with every Quantum Laser Sintering QLS™ 350 system it sells commercially starting in the first quarter of 2021.

“We are very excited to partner with Nexa3D, the company that is breaking traditional additive manufacturing (AM) speed and productivity barriers, to deliver our first ever PBT laser sintering material through their ultrafast QLS 350 system,” said Hugo da Silva, VP of Additive Manufacturing at DSM. “As we have already witnessed throughout Covid-19, the manufacturing industry sees AM as a viable path to sustain production and build resilient supply chains. This requires accelerated adoption of AM technology and at DSM, we are moving quickly to introduce new materials and collaborate with partners whenever possible.”

This partnership underscores both companies’ strong commitment to accelerate the adoption of sustainable additive manufacturing for series production of electrical connectors, automotive electronics and lighting applications through innovative collaborations that are designed to unlock the full potential of additional performance polymers for additive manufacturing.

“We are thrilled to partner with a company of the caliber of DSM, one of the world’s leading providers of additive manufacturing performance polymers, to jointly deliver the next generation of series production capabilities to our customers,” said Avi Reichental, Co-founder and CEO of Nexa3D. “We believe that this collaboration is essential given our combined capabilities to improve polymer production performance orders of magnitude and that this is the right time to realize the combined potential that this partnership unlocks for the benefit of our expanding customer base in the innovative automotive and electronic industries.”

The use of laser sintering PBT materials is expected to increase exponentially over the next decade, driven primarily by accelerating innovations in the automotive, electrical, and electronics industries. This trend is especially observed in the automotive industry, where the need for lighter, more sustainable, lower maintenance materials rules future designs. The use of engineer-grade materials such as PBT is expected to increase due to the need to minimize issues surrounding the corrosion of metals and their associated high costs.

Arnite® T AM1210 (P) is the first ever PBT powder for laser sintering and is, since its launch in 2019, highly desired and well-known for its series production performance in making end use parts, such as automotive electronics and applications, that need to function under high temperatures. Arnite® T AM1210 (P) has the same dielectric properties as material used in injection molding processes, making it a material familiar to engineers. Developed for a wide sinter window, the powder is extremely easy to print. Additionally, Arnite® T AM1210 (P) is environmentally friendly with a high reuse rate of >60% and recyclable to the extent that the material can be brought back to the powder bed process.

To learn more about the DSM and Nexa3D partnership, check out this media kit and watch these videos.

Throughout Covid-19, both companies continue to expand their product portfolios as well as their partnerships and collaborations. This has enabled more customers to strengthen their design agility and supply chain resiliency by compressing their design and manufacturing cycle, effectively reducing the time required to produce functional prototypes and production parts from hours to just minutes.

DSM – Bright Science. Brighter Living.™

Arnite® is a brand of Royal DSM, a global purpose-led, science-based company in Nutrition, Health and Sustainable Living. DSM’s purpose is to create brighter lives for all. DSM addresses with its products and solutions some of the world’s biggest challenges whilst creating simultaneously economic-, environmental- and societal value for all its stakeholders; customers, employees, shareholders, and society-at-large. DSM delivers innovative solutions for human nutrition, animal nutrition, personal care and aroma, medical devices, green products and applications, and new mobility and connectivity. DSM and its associated companies deliver annual net sales of about €10 billion with approximately 23,000 employees. The company was founded in 1902 and is listed on Euronext Amsterdam. More information on Arnite® and DSM’s additive manufacturing activities can be found at www.dsm.com/additive-manufacturing/

Find us on:

Facebook

Twitter

LinkedIn

Youtube

Media Contact

Mirella Kimpen

DSM Additive Manufacturing

+31 6 1177 9305

mirella.kimpen@dsm.com

About Nexa3D

Nexa3D makes ultrafast industrial grade polymer 3D printers affordable for professionals and businesses of all sizes. The company’s printers are powered by proprietary Lubricant Sublayer Photo-curing (LSPc) and Quantum Laser Sintering (QLS) technologies that increase print speed and productivity sustainably by orders of magnitude. The company’s partnerships with world-class material suppliers unlocks the full potential of supply-chain approved performance polymers that are tailored for faster prototyping and volume production applications. The company’s end-to-end validated workflows are designed to maximize productivity by reducing 3D printing cycles from hours to minutes and sustainability by minimizing waste, energy and carbon footprint. To learn more, visit www.nexa3d.com.

Media Contact

Josh Turner

Silicon Valley Communications

+1-917-231-0550

turner@siliconvpr.com